Jason Carlton

Active Member

What is a BEC?

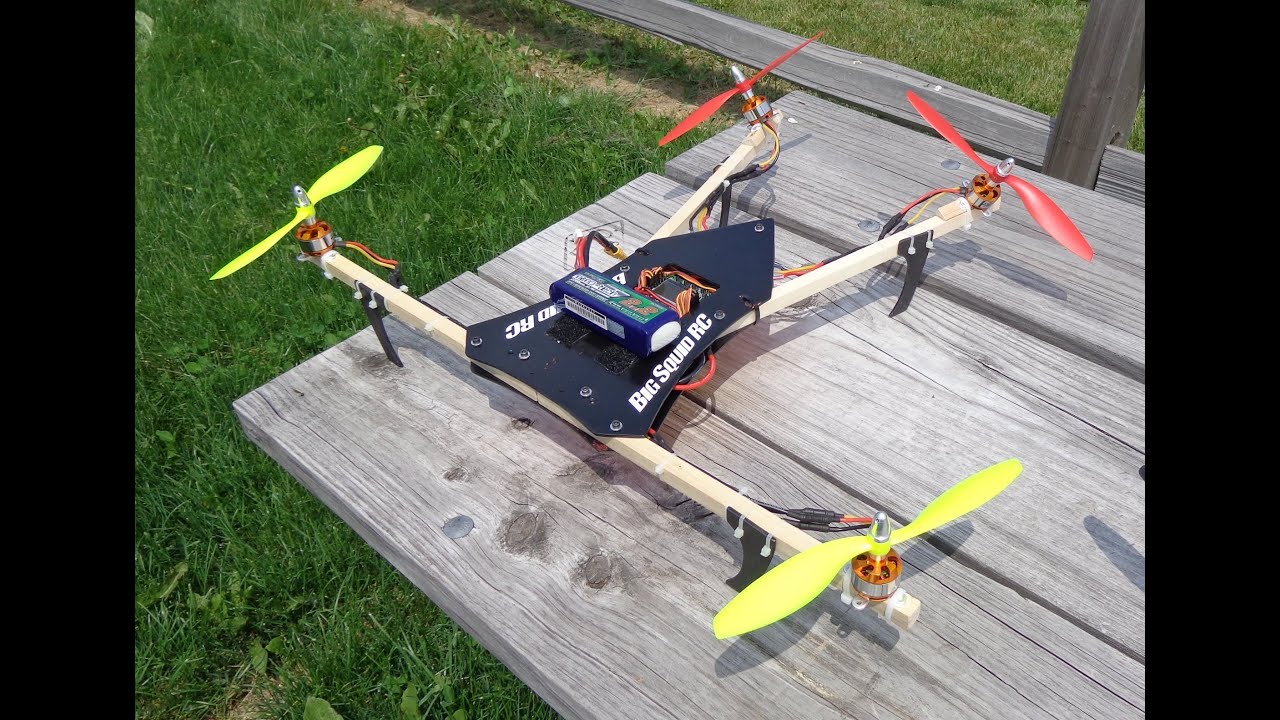

I'm assuming youve placed your battery between the two main plates?

How did you distribtue power to all motors and reciever, I was planning on buying a small power distribution board - http://www.hobbyking.co.uk/hobbykin...r_Distribution_Board_DIY_8_x_output_PCB_.html

Is this a good idea?

I'm assuming youve placed your battery between the two main plates?

How did you distribtue power to all motors and reciever, I was planning on buying a small power distribution board - http://www.hobbyking.co.uk/hobbykin...r_Distribution_Board_DIY_8_x_output_PCB_.html

Is this a good idea?