flyingpotato666

Member

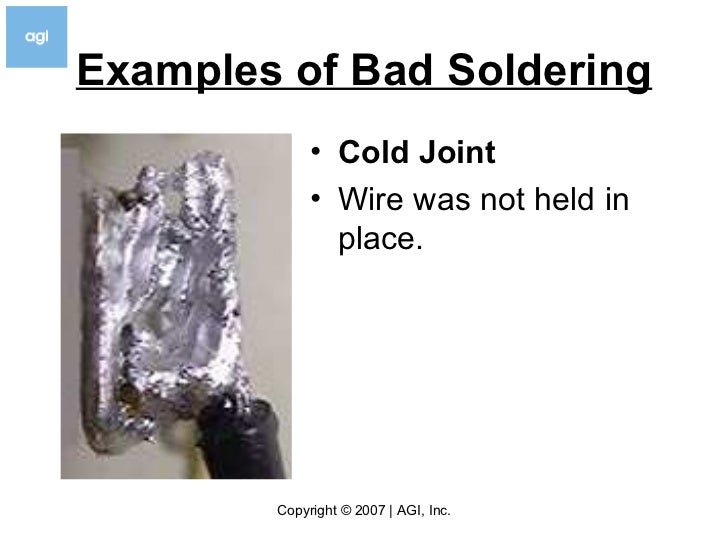

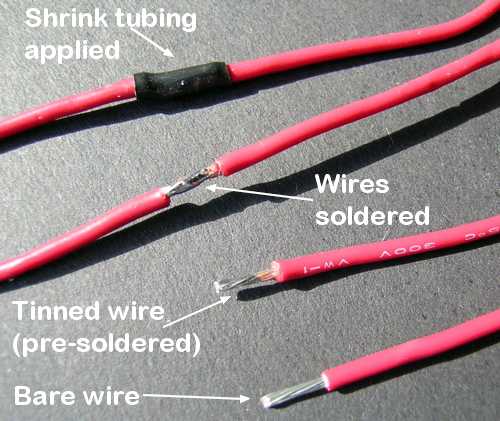

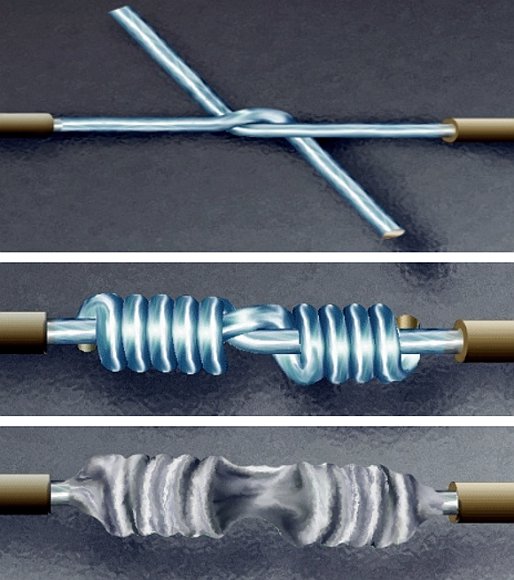

So I need to solder my motors and speed controllers, so first I tried soldering for the first time on some spare wire. What i did was i twisted both the wires together (without the insulator) and clumped them into a ball and soldered, or should i say tried to solder... I attached a picture of what it looks like in the end, its pretty strong but just from looking at the picture do you think the soldering is good? Ive read in some places that the more solder the better so I used a lot, and in other places they say use the least possible amount you can... Please if you see anything wrong with what I did please tell me, im planning to practice one more time on another wire and then solder the motors and escs

Thanks!

Thanks!