These are good suggestions. I did email quadlugs, and asked him how sales where. He said its been hit and miss. He lives in my state. Flitetest have the market because of the testing they do. I can't put that much time into this business unless I get laid off. (Which is more of a reality each day). I did notice the these guys who have not made the final product before funding it like, Lily drone, Zano, and Ethos that is not a good way to go. I see that the publicity and negative publicity will shoot a business down faster than a speeding bullet or falling drone.

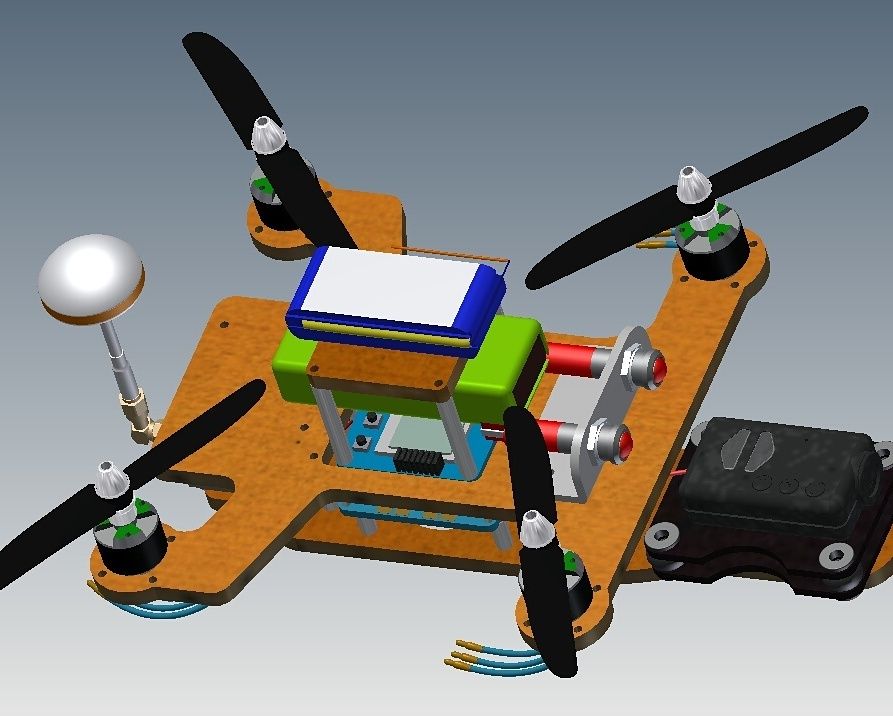

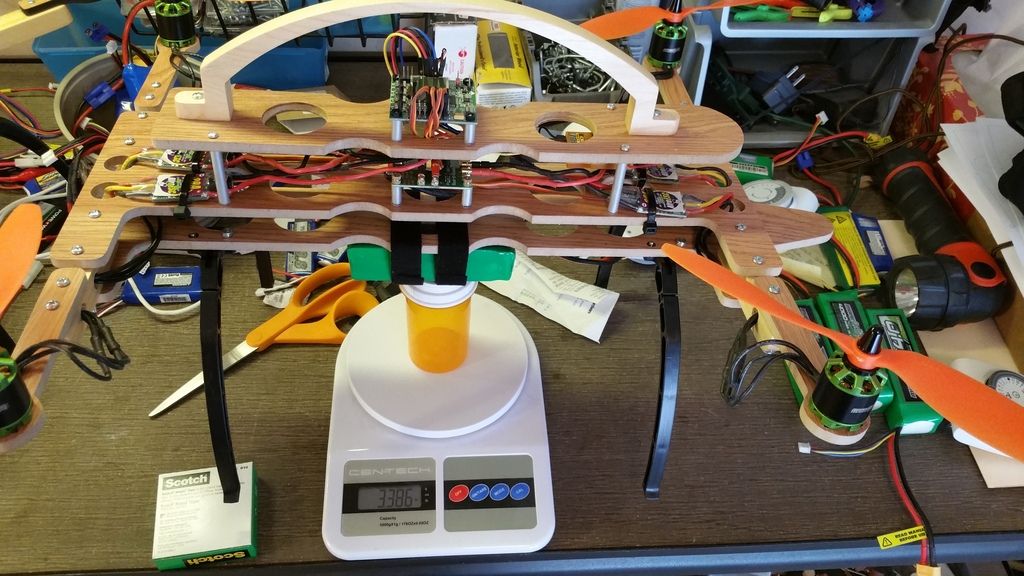

The appeal is the wood, I hope it also the 2 part design for easy repairs. The top contains the fc, receiver, and the bullet connected motors. The second part or bottom contains the escs, the power distribution board, the lights, landing gear, and camera junk. To un assemble it, you remove 4 or 6 screws on the top, unplug the motors wire from the esc, un plug the battery monitor, and disconnect the bullets from the motors. To identify the bullets I use two types of color paint pens, green and white. I use the same paint pen and mark each motor in braille. One dot for one. Two for two, etc. I also use the same paint pens to mark the motor wire connectors, and the escs. One of my secrets I will share is how to tell which motor is spinning in the right direction. I will put the prop on loose. It will slowly spin it in its direction enough to see what is cc or ccw. I have bad eyesight. It works every time.

I also use different color wires in my receiver to fc wiring. I steal the wires from those balance plugs and re wire them with jsts. Works really slick and is easy to identify if you stick to the same pattern.

All of this information is included on the directions for each plan if sold. lol I use the word if lightly.