HDtallrider

Well-Known Member

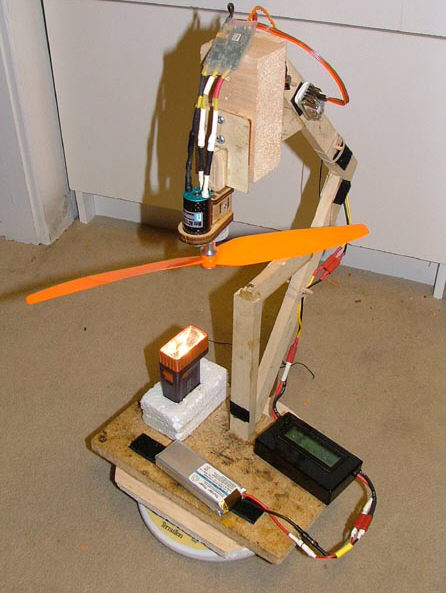

I was unsure where to put this thread. I just improved the performance of some not very good motors and it cost more than it was worth. Bear with me here. I'm an avid audiophile and I was sending some cables and components out to be cryogenicaly frozen. This has quite a dramatic effect. I had 4 Gartt LM 2212 920kv motors that I was considering junking. Instead I sent them off with my audio stuff. I first made a rig that allowed me to measure the lifting power of each motor. The rig I used showed 610 grams with a 9.47 prop on the best motor. When I got them back I tested them again. They were more closely matched and the stronger motor now showed 715 grams! The downside with cryo treatment is the $8.00 per motor cost ( on $10 motors ) and the deformation of some of the cheap plastic and metal used. The better the material the better it responds. When I finally get around to buying better quality, more expensive motors I will do this again. The Gartts are not going to last long because the cheap materials couldn't tolerate the process. Next time I'm going to try treating ESC's and see if there is any improvement to them. Not sure how I can measure that. Food for thought...