UPDATE: The magnets on the motor are too loose, as the epoxy failed

I wondered about that for a split second, never thought to mention it. The electromagnets are softer metal than the bell (usually, brushed motors are the opposite). To do this, you'd probably have to send out just the coil and shaft. Glues and epoxies won't come through this process very well, as the metals are going to be a lot more malleable.

@HDtallrider Did a little informal experiment of sending motors and ESCs off to be cryogenically treated.

Explanation of what this process is:

This process usually consist of taking parts and cooling them in multiple stages to really cold temperatures, and then slowly heating them back up multiple times. This is very common practice among the audio community and audiophiles like@HDtallrider . The aviation, automotive industry, and military also uses this process. The theory is that as the metals are cooled and heated that they are rearranged in a more crystalline structure. This affects the conductivity of most metals, often making them more conductive. Having less resistance should not only yield more thrust, but less heat.

@HDtallrider Has done this with audio equipment for years andit has affected the sound. After getting into quad-copters he decided to try this on a pair of really cheap motors and ESCs. The motors fared pretty well (save for a problem with the bearings), but the really cheap ESCs began de-laminating.

According to @HDtallrider's previous experience cheap parts and PCBs don't fare the process too well, but better PCBs and parts usually come back just fine.

Seeing that the cheap motors had more thrust after the treatment he decided to do a more formal and accurate test.

He and I talked a little through PMs trying to get an idea of how/what to test. Here is what we came up with:

Thrust:

Resistance or inductance:

I found that you cannot test resistance across the coils without really expensive muti-metre. But inductance is better for a coil. The question is what all can we determine with just inductance? Neither of us have equipment to determine self-resonant frequency, and without that you cannot calculate capacitance. link.

Break-in Period

I was thinking of just doing multiple test where you run them for a little. I would be afraid of just putting them on a quad and flying as you get dirt and possible crashes to hurt the test.

Questions:

How to test the "break in period"

Know of a way to test torque?

Anything else to test?

See a better way to do something?

Suggestions?

Alert!!!!! Don't do this yet!!!!! Remember when I said I have just enough knowledge to get in trouble? This is a good example. I just got a SunnySky 2216 motor and a ZTW Spider 30a ESC back. The ESC is toast. The motor shows some stator and wire distortion but the worst effect is the epoxy that holds the magnets to the bell disintegrated. I went back and disassemled all the Gartt motors from before and I could remove the magnets with my fingernail. I don't know why they didn't just fly apart. I don't have the scientific background or education to do this experimenting properly. This is a prime example of learning the hard way.

I wondered about that for a split second, never thought to mention it. The electromagnets are softer metal than the bell (usually, brushed motors are the opposite). To do this, you'd probably have to send out just the coil and shaft. Glues and epoxies won't come through this process very well, as the metals are going to be a lot more malleable.

@HDtallrider Did a little informal experiment of sending motors and ESCs off to be cryogenically treated.

Explanation of what this process is:

This process usually consist of taking parts and cooling them in multiple stages to really cold temperatures, and then slowly heating them back up multiple times. This is very common practice among the audio community and audiophiles like@HDtallrider . The aviation, automotive industry, and military also uses this process. The theory is that as the metals are cooled and heated that they are rearranged in a more crystalline structure. This affects the conductivity of most metals, often making them more conductive. Having less resistance should not only yield more thrust, but less heat.

@HDtallrider Has done this with audio equipment for years andit has affected the sound. After getting into quad-copters he decided to try this on a pair of really cheap motors and ESCs. The motors fared pretty well (save for a problem with the bearings), but the really cheap ESCs began de-laminating.

According to @HDtallrider's previous experience cheap parts and PCBs don't fare the process too well, but better PCBs and parts usually come back just fine.

Seeing that the cheap motors had more thrust after the treatment he decided to do a more formal and accurate test.

He and I talked a little through PMs trying to get an idea of how/what to test. Here is what we came up with:

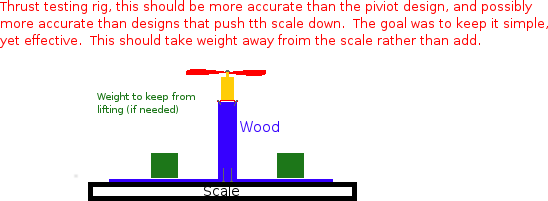

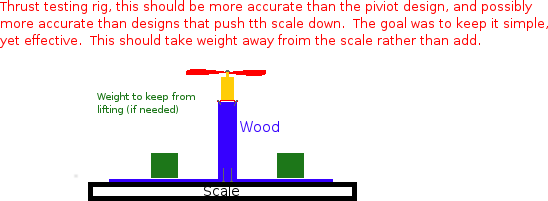

Thrust:

Resistance or inductance:

I found that you cannot test resistance across the coils without really expensive muti-metre. But inductance is better for a coil. The question is what all can we determine with just inductance? Neither of us have equipment to determine self-resonant frequency, and without that you cannot calculate capacitance. link.

Break-in Period

All electrical parts have a break in period. If you test a brand new component and the test it again after a 100hours of use you will find there is a difference. After a part is cryoed that break in period starts again. Folks will notice a difference as the parts get some time on them. I have a small cheapy audio system that I use to break in cables and such. I will put in a disc I have that has music and vocals that cover a huge frequency range. I will put it on repeat and run it non stop, on low volume, for a week before I put it in my main system. I don't know how to address this regarding quads. More food for thought......

I was thinking of just doing multiple test where you run them for a little. I would be afraid of just putting them on a quad and flying as you get dirt and possible crashes to hurt the test.

Questions:

How to test the "break in period"

Know of a way to test torque?

Anything else to test?

See a better way to do something?

Suggestions?

Last edited: